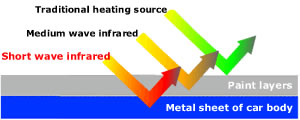

There are 3 types of infrared lights: short wave, medium wave, & long wave.

The difference is the penetration depth.

Primelamp adopts short wave infrared system, because its heat can penetrate through paint layers,thus provides bottom-up (inside-outside) cure,

which remarkably reduces energy consumption & drying time.

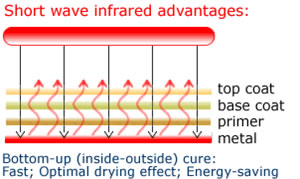

Shortwave infrared advantage

Equipped with specially-designed bulbs for car paint curing, its heat can powerfully penetrate directly into inner paint layers to accelerate molecular reaction of paint. Thus it provides super fast drying. Such bulbs adopt short wave infrared technology, which cure paints in a bottom-up way, so its drying is super fast, energy-saving, & offers optimal drying effect.

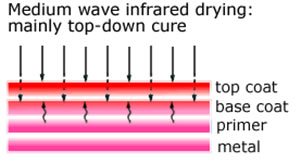

Mediumwave infrared drying

Medium wave infrared drying can NOT penetrate into bottom paint. So the cuing is mainly top-down. While outer layers are dry, bottom layers are wet. Thus the drying is uneven & provides poor quality of finish / coating.

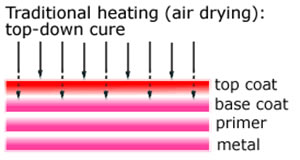

Traditional Heating (air drying)

Traditional heating (air drying) can NOT penetrate into inner paint. So the cuing is just top-down. While outer layer is dry, inner layers are wet. Thus the drying is uneven & provides poor quality of finish / coating.

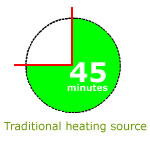

shortwave infrared ray and traditional heating source

Primelamp's IR paint dryers remarkably reduce drying time. It quickly dries polyurethane paint (double-component paint) for limousine, single-component coating & water-based paint. For double-component paint, total cure time is within 15 minutes, & for single-component coating, within 5 minutes; while traditional dryer will cost 45 minutes.

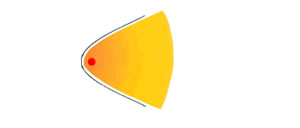

Reflector

The reflector is specially designed to direct all the energy from the lamps towards treated panel. So the reflector is wide-angle, high-light & energy-focused.

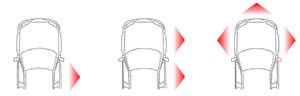

Paint Dryer

Most body shop repair jobs are for small & mediume damages, mostly on front, back & side panels. Traditionally, spray booth is used to dry those small surfaces of the body, thus bottle-neck problem will ensue if there is heavy work flow. Unlike spray booth, infrared dryer proves to be more efficient & time saving on small body damages since they allow direct in-depth heat application on the treated panel.